[ Schaeffler ]

Schaeffler OPTIME Condition Monitoring

What is OPTIME Condition Monitoring and how does it work?

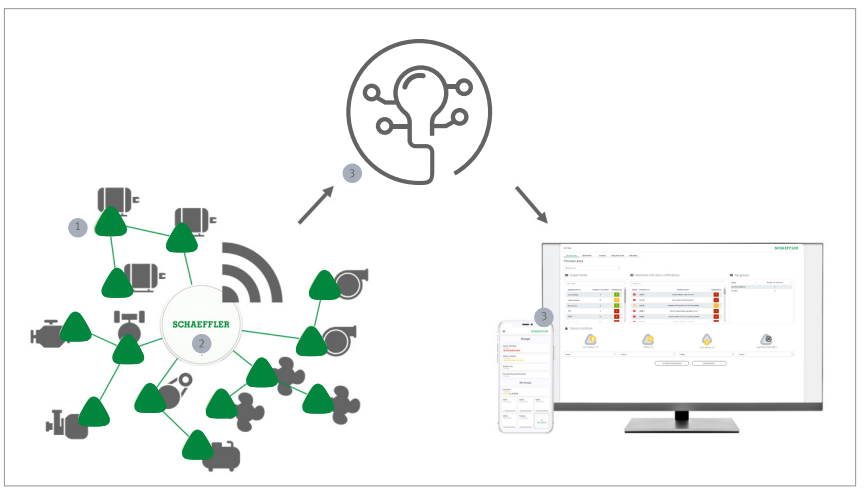

Schaeffler OPTIME Ecosystem

Solution Components

What is Schaeffler OPTIME CM?

In the OPTIME Ecosystem, which combines intelligent condition monitoring and lubrication, Schaeffler OPTIME CM is an easily scalable condition monitoring solution. It has been developed for various purposes in industry and is recommended for a range of rotating machines with a speed of 120 rpm*-5000 rpm.

During the development of the system, special attention was paid to the very simple commissioning, problem-free expansion and versatile use of the solution. The effort for the user was kept as low as possible for each individual process step. These features make Schaeffler OPTIME CM particularly suitable for condition based monitoring of a large number of machines also for hazardous areas.

Benefits of Schaeffler OPTIME CM

- Cost-efficient monitoring

- Monitoring hundreds of rotating machines for just a few cents per day – up to 50 percent cheaper than manual monitoring with handheld measurement devices

- Solutions available for the hazardous areas

- Quick to install

- Installing the sensors and setting up the app takes just a few minutes – no previous knowledge is necessary

- Use expert knowledge

- Digital Service provides professional diagnoses based on expert algorithms and machine learning, available 24/7 via app – so you always make the right decision

- For beginners and advanced users

- Easy handling, offers decisive information and extensive extensions suitable for different users and needs

Schaeffler OPTIME Ecosystem

Solution Components

1. Sensors

The battery-operated sensors can be mounted quickly and easily on the machines and record vibration and temperature data of the monitored unit. The wireless mesh network enables automatic data exchange between all connected units.

2. Gateway

The gateway receives the data sent by the sensors and transmits it to the cloud. One gateway can cover 50 sensors.

3. Digital Services

In the cloud, continuous, automatic analyses are carried out and early warnings are sent out in case of beginning and imminent failures. The results are based on algorithms derived from Schaeffler‘s rolling bearing knowledge and condition monitoring expertise as well as machine learning. All results are available in an easy-to-use smartphone app and a web-based dashboard. The functions are tailored to the needs of the users and their individual work processes.

Schaeffler OPTIME Ecosystem?

Digital Service

OPTIME Digital Service is a cloud-based solution and can be used via mobile App and web applications for desktop browsers, e.g. in control rooms or at the workplace. OPTIME Digital Service, is made available to the customer after subscription to the service by creating a dedicated customer area within the Schaeffler Cloud. The OPTIME installation is managed via the mobile application or the OPTIME Dashboard. OPTIME Digital Service includes mandatory and optional service components.

Description – Mandatory Services

Digital Service Tenant

- Provision and access to your own customer area in the Schaeffler Cloud.

- User access and management.

- Commissioning and activation of sensors and gateways via the mobile app.

- Hardware allocation, including the creation of plants and machines, and corresponding groups.

- Access to mobile and web applications for desktop browsers.

- Note: Schaeffler requires the name and an e-mail address of at least one key user of the customer so that the tenant can be created.

- The tenant will be set up after the customer has placed the order and will be invoiced at the beginning of the following month.

- The customer will be informed by e-mail that the tenant has been set up.

- Any agreed minimum contract period starts from the first month of the first invoicing.

Digital Lubrication Management

- Display of status information of OPTIME Smart Lubricator devices (e.g. fill level, battery status, or ambient temperature).

- Generation and display of alarms (critical lubricant level, temperature limits exceeded, back pressure too high).

- Identification of the causes of malfunctions.

- Support in the selection of lubricant and relubrication parameters.

- Remote modification of lubrication settings.

- Fees are only charged for active devices. A device is active as soon as the Schaeffler OPTIME Cloud receives data from the device.

- Gateway SIM data costs are included in the monthly fee.

Digital Service Analytics

- Vibration-based automated condition assessment of monitored machines, using algorithm-based automated diagnostics.

- Display of alarms and failure causes.

- Fees are only charged for active sensors. A sensor is active as soon as the Schaeffler Cloud receives measurement data from the sensor.

- Gateway SIM data costs are included in the monthly fee.

- Note: Schaeffler requires at least the machine type of the monitored machine for automatic analysis and alerting.

- Other optional metadata for better results are criticality, ISO class of the machine, and more.

Description – Mandatory Services

Digital Service REST API usage

- Access to REST API to retrieve data from the Schaeffler cloud into the customer system

OPTIME ExpertViewer

- Advanced vibration analysis tool for experts from experts

Schaeffler OPTIME CM

Applications

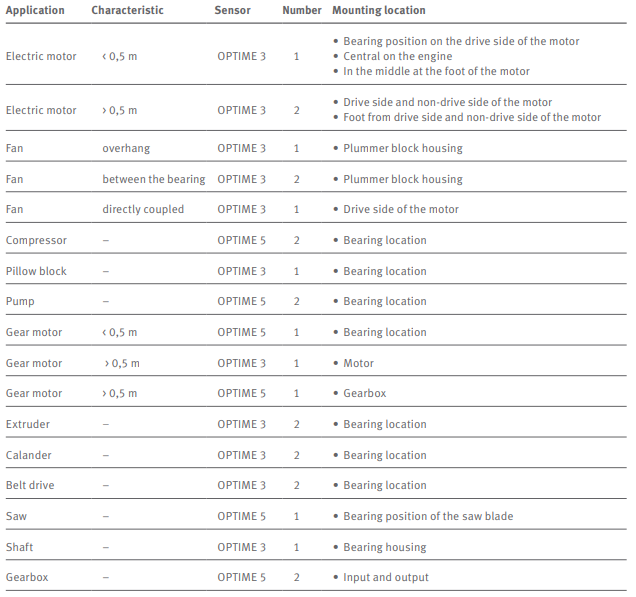

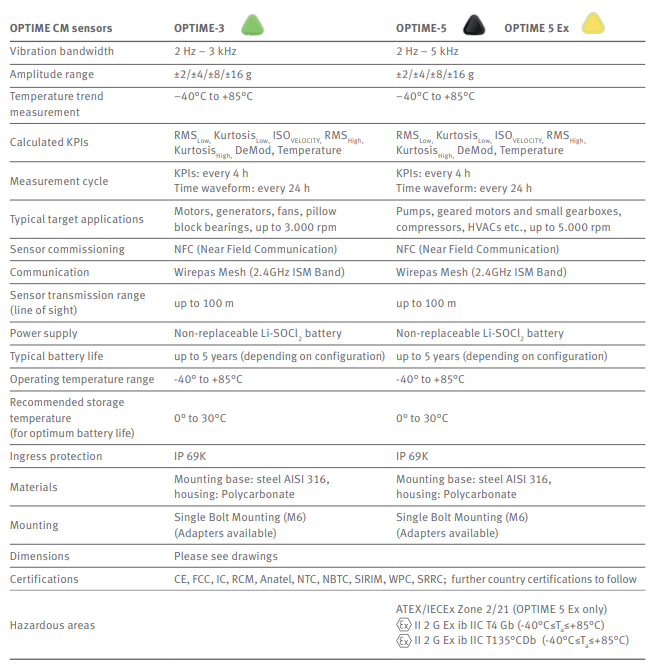

The OPTIME condition monitoring system is suitable for machines that are operated continuously or partially continuously. Furthermore, the machine should run several times a day in a stable operating condition (speed and power) for a period of approximately one hour. With OPTIME 3 sensors, machine speeds from 120 rpm* to 3000 rpm, with OPTIME 5 sensors, up to 5000 rpm are recommended; the sensor variant OPTIME 5 Ex allows to extend this use case to machines in hazardous areas. When selecting the suitable combination of machine and sensor, some factors must be considered, see table.

We pioneer motion

CONCEPT 1

The lubrication system that gets straight to the point

Areas of application

- Electric motors.

- Pumps.

- Ventilators.

- Conveyor belts.

- Machine tools (auxiliary units).

- Cable cars (track rollers).

Technical characteristics

- One outlet.

- Lubricating media: Oil and grease up to NLGI 2*.

- Lubricant volume: 60 cm3 or 125 cm3.

- Pressure build-up: max. 5 bar.

- Operating temperature: -20 °C to +55 °C.

- Operating principle: gas-driven.

- Discharge time at 20 °C: 1 to 12 months.

- Protection class: IP68.

- Certified:

- II 1G Ex ia IIC T6 Ga

- II 1D Ex ia IIIC T80 °C Da

- I M1 Ex ia I Ma

- Protection class: IP68.

Product advantages

- Flexible: Pre-filled cartridges with ARCANOL lubricant or empty cartridge for filling with customer’s grease.

- Sustainable: Empty cartridges can be filled up to three times and are environmentally friendly.

- Cost-effective: Good price-performance ratio within comparable equipment class.

- Plug & Play: Easy changeover to automatic lubrication (no special tools required).

- ATEX-certified: Safe lubrication in hazardous areas.